|

|

Draw Knife |

Edge Angles

The Tormek KJ-140 or SVM-140 knife jigs work well to hold this.

CB's USB Projection Calculator is recommended for calculating setup for Tormek knife jigs. (The simpler Projection Calculator is also still available. This one is web-based and does not require Excel.)

|

The feel and beauty of finely crafted wood ... the refreshing smell of your workshop ... the absorbing joy of cutting and joining that makes the hours race by ... These are the reasons you love woodworking. Jack Neff |

If you want to grind a flat bevel on the edge and you are using a Tormek, watch the video below on using the Tormek MB-102 Muti Base.

|

General Guidelines |

|||||||

|---|---|---|---|---|---|---|---|

|

Tool Usage |

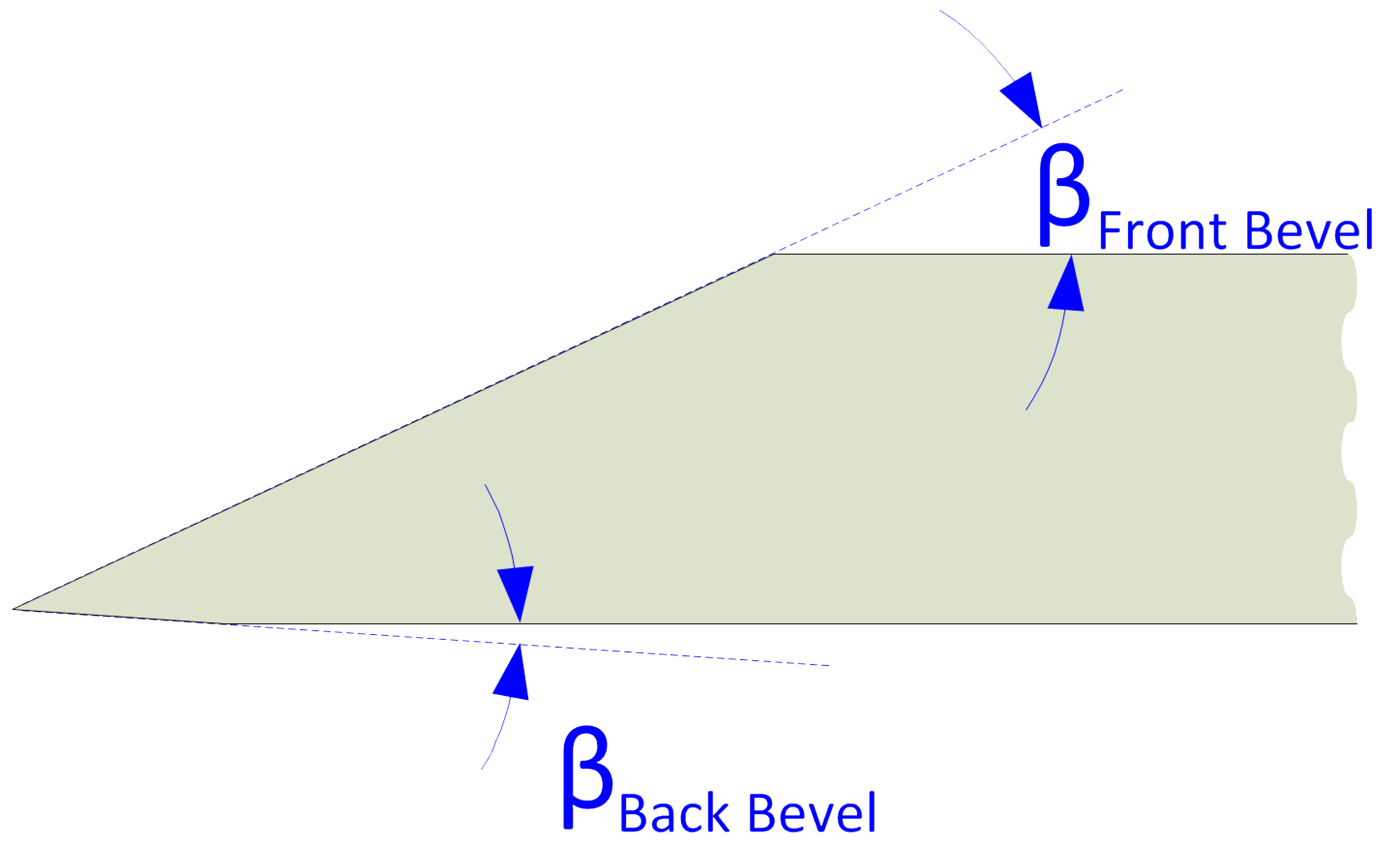

βFront Bevel | βBack Bevel |

Sharp

|

Comments |

|||

|

Range |

Recom-mend |

Range |

Recom-mend |

||||

| Bevel Down | 25° - 30° | 28° | n/a | n/a |

|

I've seen recommendations for βFront Bevel which range between 15° and 30°. The very accomplished chairmaker, Curtis Buchanan, recommends an angle of 28°; I won't try to second-guess him. (His sharpening approach is shown in the video below.) |

|

| Bevel Down | 20° - 25° | 23° | 2° - 5° | 5° |

|

||

The shape of the grind used is a call best made by the tool's use, based on their own experience. Additional notes are available on separate web pages for Grind Profiles, and Micro / Secondary Bevels.

Online Calculators that can be used for sharpening knives.

At about 1:03:00, there is a good discussion about sharpening draw knives.

Regardless of what might be the reason to want a flat bevel, Sèbastian and Wolfgang show how to achieve it with your Tormek wet sharpening system, They will also touch upon the differences between the different types of bevels.