|

|

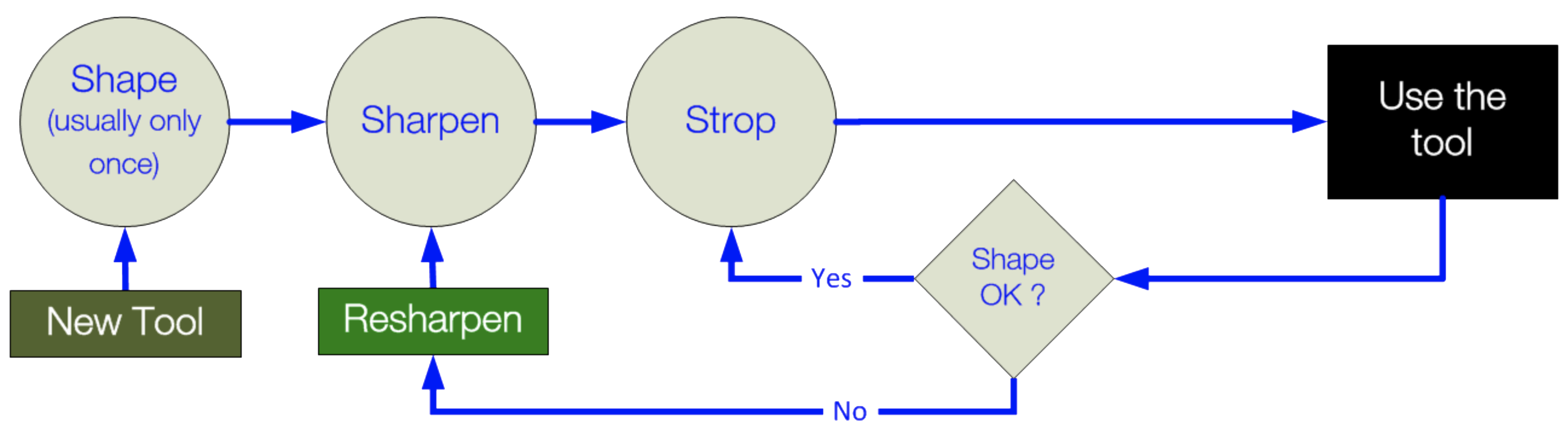

General Information on Sharpening

|

|

Typical Grinding Media Used

Shaping the ToolWood carving tools are typically only (re)shaped once in their lifetime. And that happens when the carver gets the tool from the manufacturer, and adjusts it to their own preferences. But, this is a pretty substantial process for carving tools.

|

|

Typical Grinding Media Used

Sharpening the ToolCarving tools are typically sharpened

|

|

Typical Grinding Media Used

Stroppinging the ToolCarving tools are typically stropped often. Very often.My personal preference is to hone on a wheel at the start of the process, and then later, hone on either a leather strop or shaped MDF with a honing paste of some sort. Note: When honing or stropping, the side to start on is the one where the grinding was last done. If you start on the other side, the burr will get ripped off and you will probably have to re-grind the edge. Dr. Larrin Thomas’ book, Knife Engineering: Steel, Heat Treating, and Geometry (2025), discusses burr removal quite well. |

|

Some good web sites for learning about stropping carving tools include : |