|

|

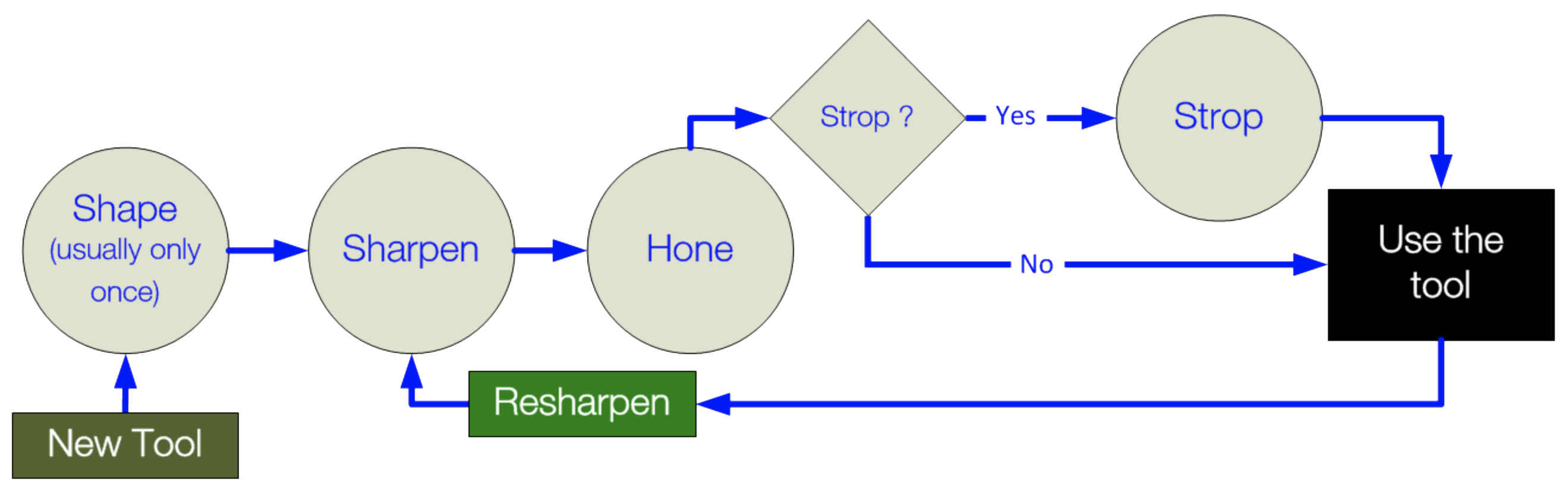

General Information on Sharpening

|

|

Typical Grinding Media Used

Shaping the ToolWoodworking bench tools are typically only (re)shaped once in their lifetime. And that happens when the woodworker gets the tool from the manufacturer, and adjusts it to their own preferences. |

|

Typical Grinding Media Used

Sharpening the ToolWoodworking bench tools should be resharpened often. Softer woods like cedar don't require that the tool is resharpening as often; but harder woods definitely necessitate the need to be resharpened often. Mallet work can shorten the time between sharpenings even more.And of course, the tool must be resharpened whenever the woodworker drops the tool (after bandaging their foot of course). |

|

Typical Grinding Media Used

Honing the ToolSome woodworkers combine honing and stropping together; this can certainly be done on marking knives. But, for chisels or plane blades, these are two separate steps.Note: When honing or stropping, the side to start on is the one where the grinding was last done. If you start on the other side, the burr will get ripped off and you will probably have to re-grind the edge. Dr. Larrin Thomas’ book, Knife Engineering: Steel, Heat Treating, and Geometry (2025), discusses burr removal quite well. |

|

Typical Grinding Media Used

Stropping the ToolSome woodworkers choose not to strop their tools. There was a great debate on Fine Woodworking's podcast #178 about this. Bob Van Dyke advocated it whilst Mike Pekovich seemed to pooh poohed it.In Sharpen This, Christopher Schwarz uses the term “polishing” for this activity. He advocates that it makes the edge more durable. Chapter 7 covers this well and is worth the read. My experience has been that stropping is especially useful when using the SJ-250 Japanese Waterstone for honing. I do not have finer stones (e.g., 12,000 grit Japanese waterstones), so stropping seems to cover that gap for me. |