|

|

Axes & Hand Axes |

Edge Angles

The U.S. Forest Service's manual, One Moving Part: The Forest Service Axe Manual notes that an ax must do three things to cut efficiently:

Give me 6 hours to chop down a tree and I'll spend the first 4 sharpening the ax.

Abraham Lincoln

Guidelines shown below are for Included Angles (α).

Notes are also available on a different web page for Micro / Secondary Bevels.

|

General Guidelines |

||||||

|

Ax Type |

α |

Secon-dary Bevel |

Sharp

|

Notes |

||

|---|---|---|---|---|---|---|

|

Soft Wood |

Hard Wood |

|||||

| Carpenter Axes | 20° | 25° | 5° |

|

Grind the edge so there is a longer side facing the wood. | |

| Carving (hand) Axes | 20° | 25° | 5° |

|

Secondary Bevel Andrea Cortés recommends that the bevel needs to be wide: 9-10mm (⅜”). Andrea also recommends using an increasing progression of grits to smooth the grind to a polished surface. This can result in a secondary bevel (as shown in the picture to the right), or a flat grind, depending on which is preferred by the tool's user. |

|

| Clearing Axes | 35° - 40° | n/a |

|

A clearing axe is designed for cutting down brush and small trees. These axes typically have thin, replaceable blades. But they can be resharpened. | ||

| Felling Axes | 35° | n/a |

|

|

||

| Gardening (hand) Axes | 35° - 40° | n/a |

|

Gardening hatchets are often used to cut roots when planting or performing other gardenign activities. During such activities, the cutting edge often encouters rocks and is quickly damaged, regardless of the α angle. A greater α angle can enable the gardener to work longer before having to resharpen the tool (e.g., wait until the end of the day). | ||

| General Axes | 25° | 30° | 5° |

|

This is a guideline. Exact angles are not required. I have found that, when sharpening on the Tormek, it is quite easy to resharpen the tool quickly, and a secondary bevel is not necessary (in fact, it can make the process more difficult). If pursuing an approach with no secondary bevel, increase the α angle by 5°. |

|

| Hunting Axes | 30° | 35° | 5° |

|

||

|

|

34° - 42° | 8° - 11° |

|

The U.S.D.A.'s Forest Service has an excellent manual, One Moving Part: The Forest Service Axe Manual, which recommends these angles. This manual also recommends a convex grind. For double-bit axes, this manual also recommends The Forest Service's preferred method is to leave one edge thinner and sharper and the other edge thicker so that it doesn't have as sharp a cutting angle. Ax nomenclature refers to the thinner, sharper edge as the "keen" edge and the thicker edge as the "stunt" edge. The difference in cutting edges allows axmen to use the proper edge for the type of wood they cut. The keen edge sinks deeper into wood that is free of knots and allows the axman to remove bigger chips. The stunt edge is better in harder, dense wood, such as tree limbs or knots, and allows the axman to work without bending, chipping, or otherwise damaging the cutting edge of the ax. (pg. 15) |

||

New axes are probably sharp, but the axman may want the angle on the edge(s) adjusted to match those in the table above. Thusly, initial shaping of the edge is to be quite probable.

Shape axe blade edge(s) on the Tormek using the AX-40 Ax Jig (which replaced the SVA-170 Ax Jig) and the SG-250 grindstone graded coarse, or the DC-250 grinding wheel.

Rotation of the Grindstone: When sharpening axes, use the vertical position with the grindstone rotating towards the blade. This keeps the axe jig properly aligned to the grindstone. (If you use the horizontal position, the grindstone will tend to pull the axe away from the jig.) Also, the vertical position sharpens faster.

The sharpener can use machinist’s 12-14" bastard file.

Alternatively, an angle grinder can be used with a 120 grit flap disc. If this method is used, the sharpener must be sure to not overheat the edge, removing the temper from the steel and weakening the edge.

High speed bench grinders are NOT recommended. The U.S. Forest Services says to not use grinders at all.

It is too easy to take the temper out of the blade, and if the temper is lost, the user will get very poor service from the ax. If the sharpener does not have access to a wet grinding system, then a file or stone approach should be used (as outlined in the manual noted below). Angle grinders with flap discs don't cause such a build-up of heat if used in a limited fashion (e.g., for sharpening and not shaping the angle).

Shape axe blade edge(s) on the Tormek using the AX-40 Ax Jig and the SG-250 grindstone grade finely, or the DF-250 or DE-250 grinding wheels.

The sharpener can use machinist’s hand files. Consider starting with a 8-10" medium (or second) cut file. Finish with a 6" smooth cut file, then use this file to remove the burr.

Whetstones are available in many options for sharpening axes.

There are some who recommend that the overall grind be convex (see also, An Ax to Grind: A Practical Ax Manual from the U.S. Forest Service). I have found that using a secondary bevel removes that need, but the Tormek AX-40 Ax Jig can accomplish this grind.

|

||

|

|

|

|

Varying microbevels on the axe's edge Images courtesy U.S. Forest Service |

||

When applying microbevels, consider the approach outlined by the U.S. Forest Service. This approach applies more of a microbevel at the center of the cutting edge (C), than at the tip or toe (A).

This is diagrammed in the images to the right.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

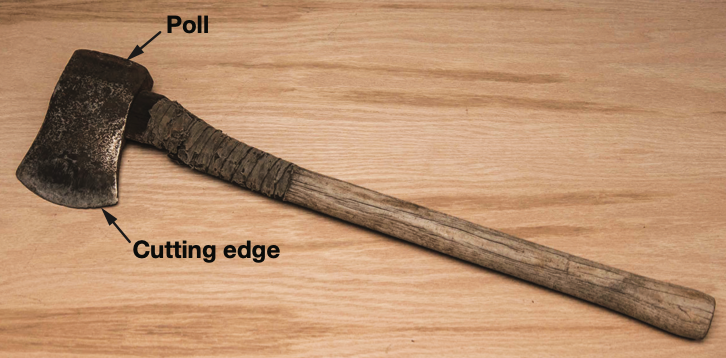

Axe Parts

Image courtesy U.S. Forest Service

If the axe's poll has gotten mushroomed out, it needs to be cleaned up. Leaving the mushroomed surface will make for danger when using the axe, just as with cold chisels.